Now that Strada Electric, Security, Air Conditioning & Heating has acquired L & M Electric, you can expect the same commitment to providing the electrical services you need to maintain ultimate comfort and convenience in your home.

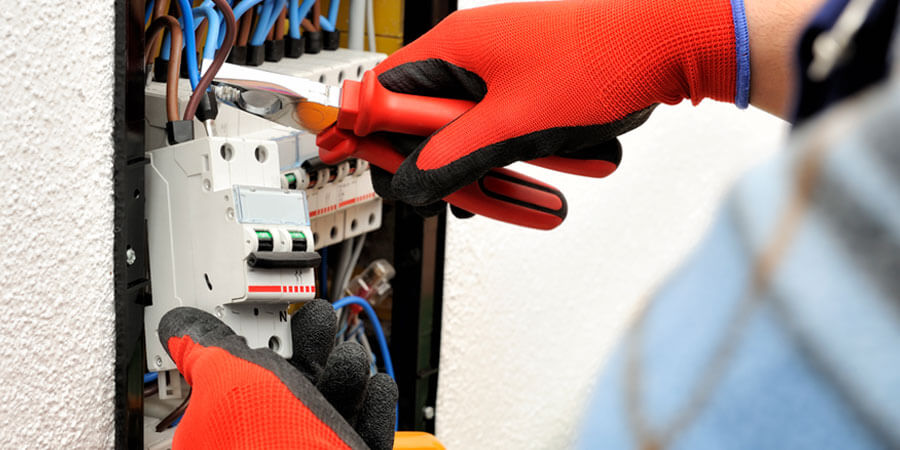

Our experienced and trained technicians are well-prepared to handle all your electrical needs. From performing routine maintenance services to providing repairs when you need them most, we have you covered. We can also install new electrical units, preventing issues like incorrect wiring, which could eventually lead to costly problems.

With our level of expertise, you can trust that we’ll get the job done safely and efficiently. Regardless of the kind of service you need, our professionals will incorporate industry best practices to provide you with the best service at an affordable rate.

We provide all kinds of electrical services, including:

Strada Is Family-Owned And Operated Company

Emergency Support

Year Labor Warranty For Comprehensive Protection

Homeowners can benefit from Strada Electric, Security, Air Conditioning & Heating’s acquisition of L & M Electric. Choosing our company means you’ll have access to technicians with years of experience.

We are fully licensed and certified, so we understand how to navigate the safety concerns of working with electrical equipment. Experience peace of mind knowing we have experience meeting all the building codes related to electrical services and keeping properties like yours safe and compliant.

With our 24/7 emergency phone support, you’ll have access to our customer service team, who will help you schedule the electrical services you need as soon as possible. We’ll arrive during operating hours to complete your repairs.

From performing electrical safety inspections to installing new lighting in your kitchen, you can count on our technicians to get the job done. We invite you to contact us today and schedule electrical services.